With more than 70% of all hydraulic system failures caused by fluid contamination, it is the number one source of hydraulic or lubrication system breakdown. These breakdowns lead to decreased productivity as well as costly component and fluid replacement. Read More…

Liquid filters are just a part of our complete line of filters and cartridges. Shelco is dedicated to providing our customers with excellent quality customer service and high quality products. This is shown through our state-of-the-art research and development team working to increase performance while reducing costs. We take pride in the fact that Shelco filters are distributed and used all over ...

SpectraPure® manufactures water purification products for marine research centers, universities, public aquariums and government agencies. Products include water filter systems, water purifier filters, reverse osmosis water filters, carbon filters, membranes, DI cartridges, bulk resin and more.

Clean Liquid Systems is a leading manufacturer of air and liquid filters. Our number one priority is to create the best filters that match the needs of our customers. We strive to have a fast turnaround while not reducing the quality of our products. Filtration is the only thing we do and ensure that we make our products right. We provide our customers with hundreds of years of experience and...

We carry over 70,000 American made hydraulic filters by Mahle, Pall, Western, Filtersoft, Vickers, etc. Replace old filters with our better-made ones for filtering systems that produce cleaner fluids. Over 3 decades of experience equals superior products, ease of ordering & budget-friendly pricing.

DAVCO Technology designs and manufactures four lines of heavily patented Diesel Fuel filtering products, heaters, water separators and one line Fluid/Oil level control products. All major Truck OEMs offer our fuel processors and 42% of all class 8 trucks being built use DAVCOs, shouldn’t you?

More Hydraulic Filter Manufacturers

Widely used in construction, military, agricultural, automotive, marine, shipping, excavation, avionics, manufacturing, oil and petroleum, paper and pulp, mining, milling and waste removal industries among others, it is important that hydraulic pumps, motors and cylinders be properly maintained by way of filters in order to avoid costly and potentially dangerous mechanical failures. Though systems vary considerably, the basic process is similar in most liquid filters. The hydraulic fluids, chemical compounds composed of oils, esters, silicon, mineral oils, water and other composite materials, are drawn through a semi-permeable, porous or chemically activated filter media.

The liquid molecules pass through this membrane while suspended particulates and chemical contaminants are inhibited. Hydraulic filters should be used even with new hydraulic fluid as it is processed and put into a given system. Often manufacturing processes result in the introduction of contaminants such as metal filings, burrs, tape, sand and other contaminants. As the operation of hydraulic equipment as well as environmental contaminants such as dirt are also common, in-line filtration is likewise important.

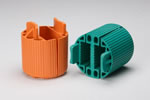

Filtration products for hydraulic systems may be purchased in media only, housing only or complete filter assembly configurations. Bulk filter media is the actual mat, barrier or chemical that traps, dissolves or contains impurities. Common materials include wire mesh, fiberglass, cellulose, paper, activated clay or carbon and other synthetic and organic fibers. The housing is the holder or frame responsible for keeping the filter media in place. This element is more commonly composed of durable materials such as aluminum, PVC, steel and stainless steel. Filter assemblies include both the housing and the media.

Common choices for hydraulic applications include in-line, tank-mounted, spin-on, duplex, off-line or recirculation, pressure, return-line, breather and suction. The technology used to implement the filters may be full flow, full flow bypass, and proportional or partial flow. The names describe the amount of fluid that actually passes through the filter during operation. Full flow hydraulic filters force all fluid through filter media, eliminating virtually every opportunity for contamination. Full flow bypass filters divert some of the fluid when the filter becomes clogged.

Proportional hydraulic filters run only a variable amount of fluid through the filtration apparatus at any given time. As improper hydraulic filtration can reduce product efficiency as much as 20%, it is important to select the proper filter for a specific application. Hydraulics and filtration professionals can provide helpful insight into product selection.

Air Filters

Air Filters Liquid Filters

Liquid Filters Filtering Systems

Filtering Systems Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services