Cartridge filters are essential filtration systems widely used across industries to eliminate impurities from liquids and gasses. These filters consist of a cylindrical cartridge, typically made of materials such as paper, polyester, polypropylene, or activated carbon. With their versatile applications, cartridge filters are relied upon in water treatment, chemical processing, pharmaceuticals, food and beverage, automotive, and various other sectors. Read More…

Liquid filters are just a part of our complete line of filters and cartridges. Shelco is dedicated to providing our customers with excellent quality customer service and high quality products. This is shown through our state-of-the-art research and development team working to increase performance while reducing costs. We take pride in the fact that Shelco filters are distributed and used all over ...

SpectraPure® manufactures water purification products for marine research centers, universities, public aquariums and government agencies. Products include water filter systems, water purifier filters, reverse osmosis water filters, carbon filters, membranes, DI cartridges, bulk resin and more.

Clean Liquid Systems is a leading manufacturer of air and liquid filters. Our number one priority is to create the best filters that match the needs of our customers. We strive to have a fast turnaround while not reducing the quality of our products. Filtration is the only thing we do and ensure that we make our products right. We provide our customers with hundreds of years of experience and...

We carry over 70,000 American made hydraulic filters by Mahle, Pall, Western, Filtersoft, Vickers, etc. Replace old filters with our better-made ones for filtering systems that produce cleaner fluids. Over 3 decades of experience equals superior products, ease of ordering & budget-friendly pricing.

DAVCO Technology designs and manufactures four lines of heavily patented Diesel Fuel filtering products, heaters, water separators and one line Fluid/Oil level control products. All major Truck OEMs offer our fuel processors and 42% of all class 8 trucks being built use DAVCOs, shouldn’t you?

More Cartridge Filter Manufacturers

Components and Functioning of Cartridge Filters

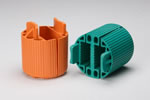

Cartridge filters comprise several key components that work together seamlessly. The cartridge housing, usually constructed from durable materials, provides structural integrity and accommodates the filter assembly. Inlet and outlet connections facilitate the fluid or gas flow. The cartridge filter media, available in different materials, acts as the primary filtration barrier, capturing contaminants while allowing the clean substance to pass through. The support core and end caps maintain the filter's structure, while O-rings or gaskets ensure a proper seal, preventing bypass and maximizing filtration efficiency.

Variations of Cartridge Filter Media

As noted,cartridge filters are made of various materials, including paper, polyester, polypropylene, and activated carbon, based on their specific properties and the intended application or design of the filter. The choice of material depends on factors such as filtration efficiency, chemical compatibility, temperature resistance, and the type of contaminants to be removed. Paper-based filter media are commonly used for general-purpose filtration applications. They offer good dirt-holding capacity and are effective at capturing larger particles and sediments. Paper filters are often employed in water treatment systems and industrial processes where pre-filtration is necessary to remove coarse impurities. Polyester and polypropylene materials, meanwhile, are preferred for their excellent chemical resistance and compatibility with a wide range of fluids. These materials are resistant to degradation from exposure to solvents, acids, and bases. Polyester filters are commonly used in applications requiring higher filtration efficiency, such as fine particle removal in pharmaceutical and beverage industries. Polypropylene filters, on the other hand, find application in industries where chemical compatibility and cost-effectiveness are crucial, such as chemical processing and water filtration. Finally, activated carbon filters utilize activated carbon media, which possesses a high adsorption capacity for odors, organic compounds, and certain chemical contaminants. The porous structure of activated carbon enables it to trap and retain these substances effectively. These filters are extensively used in air purification systems, wastewater treatment, and applications where odor control or removal of specific pollutants is required, such as the removal of chlorine in water treatment.

Variations of Cartridge Filters

Cartridge filters exhibit variations in design and components, catering to specific filtration needs. Depth filters, for instance, with their layered construction, excel in pre-filtration for water treatment systems, capturing sediments and larger particles. On the other hand, pleated filters feature a folded configuration, increasing the filtration area and enhancing efficiency, making them suitable for HVAC systems and air purification. Meanwhile, activated carbon filters leverage activated carbon media to eliminate odors and contaminants in air or water, making them valuable in environments where odor control is crucial. Finally, membrane filters, with their precise pore sizes and diverse membrane materials, find applications in critical processes like sterilization in pharmaceutical and biotech industries.

Cartridge Filter Considerations and Solutions

While cartridge filters offer numerous advantages, they are not without considerations. Clogging and pressure drop can occur due to accumulated contaminants, reducing filtration efficiency. Additionally, high-volume applications may require frequent cartridge replacements, leading to increased maintenance. To combat these challenges, manufacturers have developed advanced filter media technologies, enhancing the filter's dirt-holding capacity and reducing pressure drop. They have also improved housing designs and introduced backwashing mechanisms, enabling the removal of accumulated debris and extending filter life.

Benefits of Cartridge Filters

Cartridge filters offer several benefits that contribute to their widespread use. Their efficient filtration capabilities ensure the removal of impurities, enhancing the quality of the filtered fluid or gas. Installation and maintenance are straightforward, with easy cartridge replacement when needed. The versatility of cartridge filters allows them to be customized for various applications, ensuring optimal performance. Moreover, they prove to be cost-effective filtration solutions, providing reliable and consistent results.

Applications of Cartridge Filters

Cartridge filters find extensive applications across multiple industries. In water treatment and purification, for example, they remove sediments, particulates, and contaminants, improving water quality. Industrial processes such as chemical processing and oil and gas processing also rely on cartridge filters to maintain product integrity and equipment protection. Pharmaceutical and biotechnology sectors, meanwhile, utilize cartridge filters for sterilization and critical filtration tasks. In the food and beverage industry, these filters ensure product safety and quality. Automotive and manufacturing processes also benefit from the removal of particles and debris provided by cartridge filters, safeguarding equipment functionality. Furthermore, HVAC systems and air purification utilize cartridge filters to maintain clean and healthy air indoors. Finally, pool and spa maintenance require cartridge filters to keep water free from impurities.

Choosing the Right Cartridge Filter Supplier

To ensure you have the most positive outcome when purchasing cartridge filters from a cartridge filter supplier, it is important to compare several companies using our directory of cartridge filter suppliers. Each cartridge filter supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each cartridge filter business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple cartridge filter suppliers with the same form.

Air Filters

Air Filters Liquid Filters

Liquid Filters Filtering Systems

Filtering Systems Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services