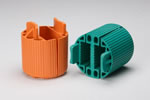

The filter itself is the frame or housing mechanism that holds the media in place as a process stream is run through them. The media or material is responsible for the entrapment, collection or dissolution of impurities. Read More…

Liquid filters are just a part of our complete line of filters and cartridges. Shelco is dedicated to providing our customers with excellent quality customer service and high quality products. This is shown through our state-of-the-art research and development team working to increase performance while reducing costs. We take pride in the fact that Shelco filters are distributed and used all over ...

SpectraPure® manufactures water purification products for marine research centers, universities, public aquariums and government agencies. Products include water filter systems, water purifier filters, reverse osmosis water filters, carbon filters, membranes, DI cartridges, bulk resin and more.

Clean Liquid Systems is a leading manufacturer of air and liquid filters. Our number one priority is to create the best filters that match the needs of our customers. We strive to have a fast turnaround while not reducing the quality of our products. Filtration is the only thing we do and ensure that we make our products right. We provide our customers with hundreds of years of experience and...

We carry over 70,000 American made hydraulic filters by Mahle, Pall, Western, Filtersoft, Vickers, etc. Replace old filters with our better-made ones for filtering systems that produce cleaner fluids. Over 3 decades of experience equals superior products, ease of ordering & budget-friendly pricing.

DAVCO Technology designs and manufactures four lines of heavily patented Diesel Fuel filtering products, heaters, water separators and one line Fluid/Oil level control products. All major Truck OEMs offer our fuel processors and 42% of all class 8 trucks being built use DAVCOs, shouldn’t you?

More Filter Media Manufacturers

Filtration is essential to the safe and productive daily operations of most industrial and commercial facilities. Water treatment, sewage, medical, pharmaceutical, food and chemical processing, aviation, aerospace, laboratory, electronic, manufacturing, automotive, building, construction, mining and agricultural industries use filter media in a number of applications in order to comply with air and water purity regulations enforced by the Food and Drug Administration (FDA), U.S. Department of Agriculture (USDA), Occupational Safety and Health Administration (OSHA) and other national and international committees.

Domestic applications for filter media likewise abound as they are implemented in heating and cooling as well as the purification of drinking water. While a single device may be used, filter media are often used in conjunction with other panels or cartridges of similar or disparate composition in order to ensure maximum filtration. Some filtering systems require the removal of even microscopic impurities as small as 0.3 nanometers, while large particle removal will often suffice in industrial settings. Insufficient filter media can lead to increased worker illness, clogging and mechanical failure of equipment as well as product contamination.

Filter media process contaminated materials in a passive manner. That is, the filters themselves are stationary and the process stream, gaseous or liquid, is pushed, pulled or otherwise forced through the filter media. Each of these fibrous or porous materials is composed of fine or coarse semi-permeable matrices that trap or chemically dissolve particulates while allowing the base product, gas or fluid, to pass through. Engineers may design filtration systems using either organic or synthetic filter media.

Organic options are increasingly popular with the advent of ‘green' manufacturing. Activated carbons or clay are used in water treatment as well as to dissolve chemical contaminants such as acids and surfactants. Diatomaceous earth is another organic filter media with high absorption and low bulk-density. A number of cellulose based materials as well as sand and paper may be used as organic filter media as well. Synthetics include a wide variety of plastics such as polypropylene, polyvinylide chloride and polysulfone. These materials, however, are under scrutiny as disposable filters are often deposited in landfills.

Other synthetics include fiberglass, glass wool, ceramics, sintered glass and porous metals. With such a variety of applications, it is important to consider the qualities, capacities and capabilities of a specific filter medium with regard for its intended use. Essential considerations include filtration grade, porosity, flow rate, filter location, stream viscosity and temperature, filter load capacity, maximum flow, efficiency and absorption.

Air Filters

Air Filters Liquid Filters

Liquid Filters Filtering Systems

Filtering Systems Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services